With vast amounts of data being constantly pulled from multiple data sources, it can be hard to accurately predict and optimize operations without a solid Business Intelligence (BI) strategy. By leveraging advanced data solutions, organizations can gain valuable insights, uncover patterns, and make data-driven decisions to improve their operations and achieve strategic goals. Inventory analytics plays a crucial role in this process by providing actionable information on inventory levels, demand forecasting, and supply chain optimization.

In today's dynamic market, inventory analytics solutions are essential for strategic inventory management – ensuring you have the right inventory, the right volume, and at the right location. With online retail sales showing no signs of slowing, the opportunity for business growth is monumental.

The challenge, however, is that without successful inventory management, it becomes difficult to evolve with the ecommerce industry and customer’s expectations around a multitude of things — not least of all product availability. By failing to have the stock to fulfill demand, you are at risk of missed sales. This can further lead to a damaged reputation and loss of future customers.

By achieving speed and accuracy, inventory management capabilities go beyond ensuring accurate inventory and automating key business processes, which was once considered to be a revolutionary development in ecommerce.

Today’s inventory control systems now also hold the key to powering business insights that can improve your ability to make data-driven decisions for increased productivity and profitability. SME’s inventory management solutions and data management capabilities provide organizations with competitive efficiency.

While balancing product availability against anticipated market demand and the ability to forecast future demand has historically been a difficult task, advanced inventory management systems leverage historical data and apply data analytics to process vast quantities of your past sales data and factoring in lead times and seasonality.

In this era of big data, an inventory system equipped with advanced analytics solutions goes beyond just managing stock. It can also provide unparalleled insights into customer behavior, product performance, and channel performance, even for large retailers with massive datasets. However, unlocking these valuable insights requires a robust data strategy and data literacy among your team members. This empowers them to effectively analyze and interpret the data, transforming it into actionable business intelligence. Now is the time to put your big data to work in a big way, but remember, investing in data literacy is crucial to maximizing its potential.

Here are two case studies where inventory management saved SME's customer time and money.

Inventory Management for Supply Chain & Logistics

This case study delves into the transformative impact of implementing an effective inventory management system within a supply chain and logistics company. The initiative yielded remarkable results, demonstrably improving efficiency and financial performance across various metrics. Holding costs witnessed a significant 24% reduction, indicative of streamlined inventory management and minimized storage expenses. Data availability soared by an impressive 97%, empowering better decision-making through enhanced access to real-time inventory information. Furthermore, inventory turn rate accelerated by 5.4%, signifying swifter product movement through the supply chain and potentially improved cash flow. These remarkable achievements stand as a testament to the power of optimized inventory management, highlighting its potential to unlock significant value for businesses in the supply chain and logistics domain.

During the project, these were the business questions the SME Solutions Group team addressed:

- How much inventory is required to meet demand while keeping stock levels to a minimum?

- How to optimize the management of stock?

- How to reduce the impact of product recalls?

- How do we prevent stock-outs or surplus of inventory?

Inventory management solutions are now equipped to apply a level of AI to power insights such as those listed above.

Challenge:

The primary challenge was the lack of consistent views across multiple data sources and lack of business user access to inventory data. The product managers had very little idea about product turnover rates and there was a large need for better production planning and performance metrics. The reports were also generated manually, and ad-hoc reports were created on-the-fly with minimal consistency or governance around queries/calculations. There also was no “real-time” analysis, generating reports from the system required customization and took time to build, not to mention the IT structure was very centralized.

Here are the key challenges:

- No insight into how much inventory is "on-order" or "in-transit"

- Need to understand what the overhead cost to holding product is

- Would like to be able to forecast product demand and supply

- Want to understand which suppliers are more reliable and charge the least in transit costs

- Trying to evaluate what location to build next warehouse

Key Performance Indicators:

|

Inventory Turn-Over

Monitor the rate at which inventory is bought and sold to improve efficiency. |

Average Days to Sell

Understand the KPIs and drivers for faster order cycle time. |

Holding Costs

Identify and reduce costs incurred by holding and storing inventory. |

At the heart of our analysis lies a rich dataset teeming with valuable information. It meticulously tracks product availability, ensuring we have clear visibility into stock levels and potential bottlenecks. Additionally, it captures sales demand, allowing us to anticipate customer needs and adjust inventory accordingly. Vendor performance is also closely monitored through vendor reliability data, enabling us to identify and partner with suppliers who consistently deliver on time and in full. By weaving together these data points, we gain a holistic understanding of our inventory ecosystem, paving the way for informed decision-making and optimized operations.

Key Initiatives:

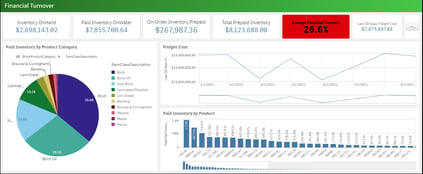

A focus of this project was to support the customer as they embraced a comprehensive DataOps approach to revolutionize their inventory management. By automating data ingestion, cleaning, and transformations through a modern DataOps pipeline, they were able to achieve real-time access to reliable inventory information. A centralized cloud data warehouse served as the single source of truth, eliminating scattered data silos and ensuring consistency across reports and analyses.

Empowering users was key. SME helped the customer select and implement user-friendly Business Intelligence tools, enabling sales reps, analysts, and executives to access current stock values and vital metrics on demand, eliminating time-consuming IT requests. The BI solution offered self-service options with pre-built dashboards and reports, further boosting efficiency and agility.

By incorporating advanced algorithms, the customer gained deeper insights into inventory trends, unlocking predictive capabilities. This enabled proactive forecasting, optimized stock levels, and reduced the risk of stockouts or overstocking, driving significant cost savings and improved customer service.

This case study showcases how a combination of DataOps, cloud-based data management, self-service analytics, and AI can transform inventory management, empowering businesses to make data-driven decisions, streamline operations, and achieve lasting success.

|

|

|

Impact:

Prior to implementing BI for Managing Inventory, there was very poor insight into operations and decisions were being made without sufficient information or context. For instance, sales reps were selling products before there was any inventory on hand, and customers were getting frustrated with limited availability/lengthy wait times for their purchases.

Modernizing the customer's BI efforts made inventory data available in real-time to all business users. The product managers now have a pulse on how much inventory is on-hand vs. in-transit, as well as backordered by supplier.

One of the most critical insights developed was a chart listing products that needed to be shipped based on months of inventory left on hand vs. a trend chart of freight prices. The product manager identified a cyclical pattern in price, and decided to delay the shipments from that vender until month-end to reduce costs. Overall, the business was able to reduce holding costs of on-hand inventory, improve the accuracy and turn rate of inventory, and give the business access to the reports they needed to be successful.

.png?width=300&height=166&name=Untitled%20design%20(44).png)

Inventory Management for Energy & Utility

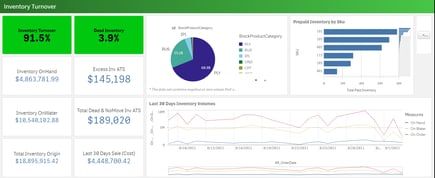

This case study is about an energy and utility customer that looked to SME Solutions Group to design and implement a solution that automated 100% of the inventory reporting allowing users to focus on data analytics instead of data gathering and data entry. As an outcome of the project, SME was able to greatly reduce the number of queries to the customer's SAP system by giving all of the shop managers across the company the same version of the data.

This effort resulted in a $4 million reduction from the customer’s balance sheets by rebalancing their inventory across storage locations and distribution centers.

Throughout the project, several key performance indicators (KPIs) were closely monitored to gauge the effectiveness of the inventory management solution. These included:

- Inventory Level by Operating Company: This metric tracked the amount of inventory held by each individual operating company, ensuring optimal stock distribution and avoiding unnecessary carrying costs.

- Turnover Ratios: By measuring how often inventory was sold and replaced, this KPI revealed inventory efficiency and identified potential issues like overstocking or understocking.

- Burn Rates: Monitoring the rate at which inventory was depleted provided insights into demand trends and helped optimize purchasing decisions, preventing stockouts and minimizing waste.

- Purchase Order Forecasts: Accurate purchase order forecasts were crucial for maintaining balanced inventory levels and avoiding costly disruptions in the supply chain. By analyzing these KPIs, the solution ensured efficient inventory management, leading to the significant cost savings achieved.

There was a lot of agile development with the end-users in order to define the complex business rules around storage locations, operating companies, and distribution centers.

Challenge:

Frustration mounted for business users grappling with meter inventory data trapped within their clunky SAP system. Managers lacked clear visibility into crucial details like current inventory levels, hindering informed decision-making. Compounding the problem, SAP's table and field structures resembled an arcane code, far from the user-friendly experience they craved. This energy and utility customer desperately needed a solution that would empower meter shop managers with a panoramic view of inventory across all operating companies. Imagine readily accessible data on turnover ratios, burn rates, and purchase order forecasts, all presented in a clear, intuitive format. Such a transformation would result in informed inventory management, optimized resource allocation, and ultimately, a significant boost to operational efficiency.

"Our goal was to provide a single version of the data and streamline reporting and testing." - SME Solutions Engineer

Key Initiatives:

Resolve SAP Extraction Issues

Some of the IT issues we resolved revolved around extracting the utility data out of SAP due to heavy regulations in their production environment. The SAP table and field structures were not very intuitive and business friendly. The reload times were longer than expected. We narrowed down the necessary dataset and removed the unnecessary noise to improve data extraction efficiency.

Develop Master Calendar Rules

Strategic master calendar rules were developed to handle various datasets including historical purchase orders, historical deliveries, current inventory levels, future planned deliveries, and future planned install rates. By creating flags during the script runtime, we were able to utilize them in our calculations efficiently to determine inventory burn rates and turnover ratios.

Taking an Agile Approach

The Agile approach embraces the constant changes that occur in the development of technology – allowing teams to break the lengthy requirements, build, and test phases down into smaller segments, ultimately delivering working software quickly and more frequently. This methodology was critical when working with the end-users to define the complex business rules around storage locations, operating companies, and distribution centers.

Impact:

The inventory management solution automated 100% of the inventory reporting allowing users to focus on data analytics instead of data gathering and data entry. We greatly reduced the number of queries to their SAP system by giving all of the shop managers across the company the same version of the data.

The initial goal for the inventory management solution was to be able to track the locations of current inventory, forecast supply, and manage purchase orders. But by the end of the first few development cycles, the solution quickly provided greater insight to current inventory levels, turnover ratios, and reports that allowed our customer to reduce their inventory liabilities by $4 million.

.png?width=700&height=127&name=Blue%20Mantis%20formerly%20known%20as%20SME%20Solutions%20Group%2c%20Inc.%20(GREEN).png)