A case study in the energy and utilities industry assessing, recommending, developing, and implementing a portal solution to achieve a 40% efficiency boost.

The Challenge

A large utility undergoing a smart meter implementation was encountering numerous gaps in the vendor management process. There was a limited line of sight into the scheduling, coordinating, and analyzing between multiple vendors responsible for ultimately getting the smart meter installed. Vendors included electricians, repair mechanics, and installation specialists. There was a disconnect between both vendor systems, delaying the smart meter install and thus the efficiency of the repair process cycle.

Gaps in efficiency were occurring in every step of the process, including:

- the time it took to send the vendor out to perform a repair.

- the time it took for the vendor to report back with completed information.

- the time it took to coordinate the smart meter installation.

- the rework repair and installation time for meter sockets that had to have more than one repair visit and subsequently an additional installation attempt.

With the average smart meter deployment exceeding hundreds of thousands of meters, when approximately 3% of those meter sockets require some type of repair, any rework drives up time and cost while decreasing efficiency.

The utility was facing delays in their deployment schedule in key areas for network development, driving up unexpected costs and compounding as deployment moved on.

Key Initiative and Approach

The key initiative was to reduce the cycle time per completed repair and reduce the number of return repair visits to the same meter socket. Before SME could recommend a solution to improve vendor management and reduce rework, there was a discovery phase of reviewing the existing process, assessing bottlenecks, and analyzing the metrics for the “as-is” process.

The SME consultants focused on data mining and stakeholder interviews to understand the process and find technology and data gaps. This holistic view would drive the recommendations on how to improve the cycle time. During the discovery phase, it was uncovered that data integrity was an opportunity for improvement as well.

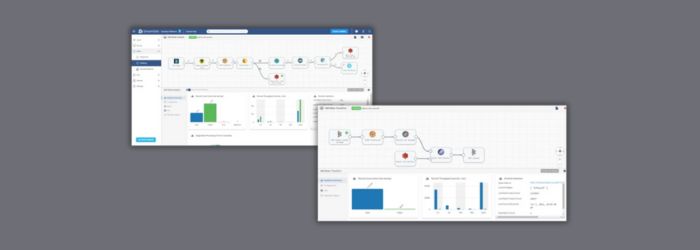

SME recommended and implemented a solution based on the findings to provide a line of sight into the installation process’s key steps. In order to do this, both structured and unstructured data (like photos from the field of the repair and installation) was aggregated to visualize the gaps and opportunities. The solution included developing a portal to receive information from the vendor daily to catch potential rework scenarios quicker and improve data integrity by requiring certain fields, adding additional columns and metadata.

It was determined that this initiative was in line with corporate strategy to modernize processes and phase out legacy processes and tools.

The Business Impact

From SME’s solution, the utility saw an approximate 60% reduction in cycle time to the repair process, enabling an effective smart meter installation. The aforementioned portal served as a data hub for the utility when it came to repairs, installs, and vendor management. In addition to the portal, the discovery phase led to the elimination of 2 steps in their process, speeding up the transition from the repair to installation.

The legacy repair to installation process took about 5 minutes per repair to digitally review and disposition the account for smart meter install and was reduced to under 2 minutes, on average. Improved and quicker vendor communication allowed the utility to make better decisions on when it was time to install. The utility used the portal to get the definitive information needed to decide on a daily basis instead of lagging a week behind, as was the case with the legacy process.

The 40% efficiency increase enabled decisions to be made quicker and increased available time to focus on strategy and planning repairs rather than dealing with rework, managing siloed data, and struggling with reporting.

A Sustainable Vendor Management Solution

This same solution can be applied to other scenarios for the utility in which multiple vendors are needed, including outsourced construction and design, vegetation management, and Electric Vehicle (EV) charging station installations.

This case study was driven by SME’s comprehensive approach to supporting our clients. The vendor management process was originally outside of the scope of work but was woven into the engagement as the client saw the value potential immediately. SME prides itself on putting the client first and being a valued partner and consultant, not a contractor.

Our consulting services consistently deliver quantifiable results that meet the unique business and technology needs for energy and utility clients. We collaborate with our clients to assist in achieving their goals by supplying talented consultants and delivering value-added solutions to achieve lasting success.

To hear more about this case study or SME's business consulting services, email us at info@smesgroup.com.

.png?width=700&height=127&name=Blue%20Mantis%20formerly%20known%20as%20SME%20Solutions%20Group%2c%20Inc.%20(GREEN).png)